customize your solutions request a quote right now!

Material Application: Electrical Insulation

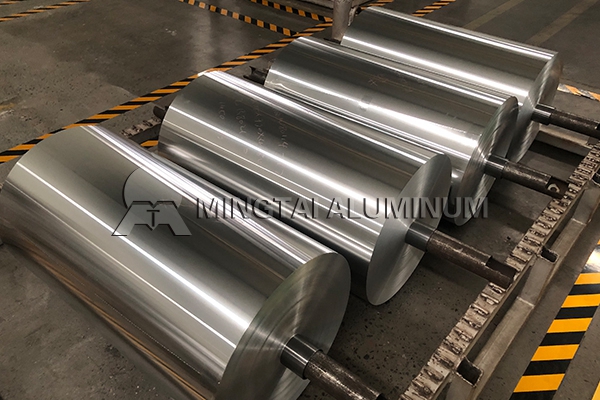

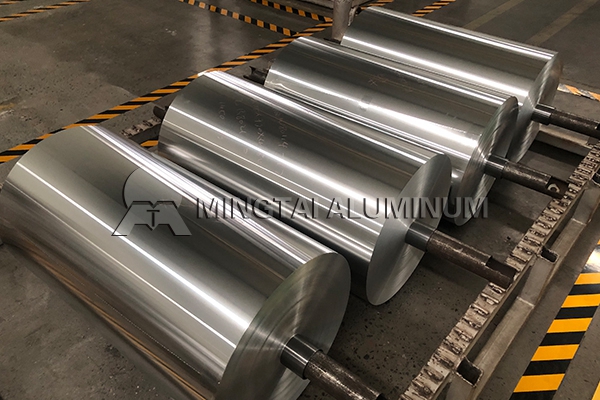

Product: 8011 aluminum foil

Project Details:

In the electrical and electronics industry, aluminum foil for insulation is a widely used and highly effective solution. Thanks to its unique properties, insulation-grade aluminum foil plays a critical role in numerous applications—preventing current leakage, reducing electromagnetic interference (EMI), and ensuring the safe and stable operation of equipment. But when exactly should insulation aluminum foil be used?

In power transmission systems, such as cables and transformers, insulation aluminum foil is often indispensable.

For cables, it acts as a shielding layer, blocking external electromagnetic fields that could disrupt signal transmission.

In transformers, it serves as winding insulation, leveraging its high conductivity to evenly distribute electric fields and minimize energy loss.

In industrial settings, insulation aluminum foil provides essential protection for HVAC ducts, motor housings, and other critical components.

In HVAC systems, aluminum foil-clad rubber/plastic insulation reflects radiant heat, reducing thermal transfer for better energy efficiency.

For motor enclosures, the foil prevents electrical interference, ensuring smooth operation of surrounding equipment.

In demanding conditions—such as marine engineering and chemical processing—where high salinity, humidity, or corrosive substances threaten insulation materials, aluminum foil proves its resilience. Its exceptional corrosion resistance allows it to maintain reliable insulation performance even in extreme environments.

Among insulation-grade aluminum foils, 8011 alloy stands out for its:

Superior ductility and tear resistance, enabling seamless adaptation to complex forming processes (bending, folding, stamping).

Smooth surface finish, minimizing gaps with insulating layers for enhanced effectiveness.

Low electrical resistivity, improving conductivity and EMI shielding for stable equipment performance.

As an industry leader, Mingtai Aluminum produces premium insulation foil through:

Rigorous material selection and advanced manufacturing processes.

Exceptional dimensional stability and uniformity, meeting high-precision demands.

Choosing Mingtai’s insulation aluminum foil guarantees reliability and safety, providing robust protection for your equipment.

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

8011 aluminum foil for aluminum bottle cap raw materials 1070 Aluminum Foil for Electrolytic Capacitors: A Key Component for Modern Electronics Alloy 8006 foil for aluminum foil container Driving Excellence in Packaging: Aluminum Foil Manufacturers in Korea Which aluminum foil is used on the inner wall of milk cartons? 8021 aluminum foil for pharmaceutical aluminum-plastic blister packaging 3004 container foil factory price 8011 aluminum foil for aluminum cooling fins

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.