customize your solutions request a quote right now!

Material Application: aluminum tape

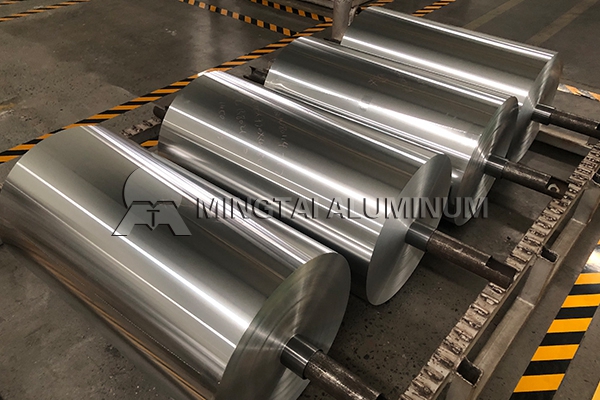

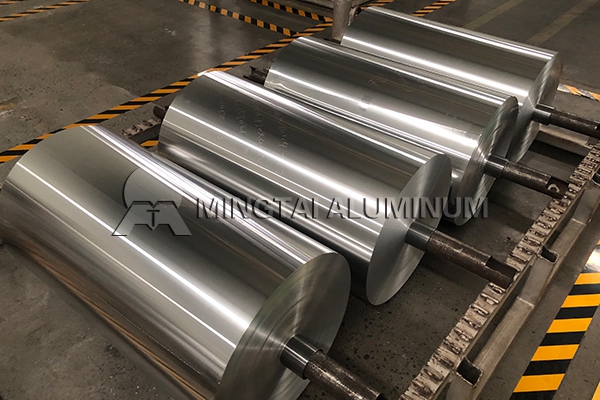

Product: 8011 or 1235 aluminum foil

Project Details:

Self adhesive aluminum foil is an aluminum foil tape commonly used in electronic products. adhesive foil uses high-quality pressure-sensitive adhesive, having a good viscosity, strong adhesion, airtight, anti-aging, good insulation properties.

The alloy and temper of self adhesive foil commonly used in the industry is 1235 adhesive aluminum foil and 8011 adhesive aluminum foil, and can be subdivided into soft and hard, single-sided and double-sided light. According to different performance requirements, the production process is not the same.

First, the adhesive aluminum foils of 1235 foil and 8011 foil have different alloy composition, and the process difference is that the annealing temperature is different. 1235 aluminum foil annealing temperature is lower than that of 8011 aluminum foil, but the annealing time is basically the same. Finished adhesive aluminum foils of 1235 aluminum foil and 8011 aluminum foil are slightly different in strength. 8011 aluminum foil’s tensile strength is higher than that of 1235 aluminum foil, at the same time, 8011 aluminum foil’s elongation is not much different with 1235 aluminum foil, just slightly higher than it.

Aluminum foil tape is divided into soft and hard state, that is, H18 and O state. Hard state aluminum foil tape’s production process does not need annealing, but sometimes need to boil oil, while soft aluminum foil tape needs to be annealed to make its performance soft. people use more 1235-O state aluminum foil tapes in the market.

Finally, aluminum foil tape is divided into single-sided light and double-sided light, single-sided light generally requires bright side outwards. Single-sided light production process is more complex, mainly in the rolling process. Single-sided light needs to open the medium, co-roll, rolling finished products, roller need to be changed; and double-sided light rolling process is relatively simple, thick material can be directly open to the finished product, no need to change roller. If it is a thin material, you need to replace the roller, and the production process is longer.

In short, the main process of tape aluminum foil is open blank, aluminum foil mill cold rolling, using the cutting machine for cutting, cleaning, annealing (choosing according to performance requirements), packaging, and the entire production cycle is about 10 days.

Aluminum foil tape is widely used in refrigerators, air conditioners, cars, petrochemicals, bridges, hotels, gas stoves, ventilation pipes, electronics and other industries. It can be used for mobile phones, PDA, PDP, LCD monitors, notebook computers, copiers and other electronic products that need the electromagnetic shielding.

RELATED PRODUCT

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

8011 aluminum foil for aluminum bottle cap raw materials 1070 Aluminum Foil for Electrolytic Capacitors: A Key Component for Modern Electronics Alloy 8006 foil for aluminum foil container Driving Excellence in Packaging: Aluminum Foil Manufacturers in Korea Which aluminum foil is used on the inner wall of milk cartons? 8021 aluminum foil for pharmaceutical aluminum-plastic blister packaging 3004 container foil factory price 8011 aluminum foil for aluminum cooling fins

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.