Home / News / Aluminum Foils for Electrolytic Capacitors: Key to Enhanced Performance in Electronics

Leave Us Message Author:Mingtai Aluminum

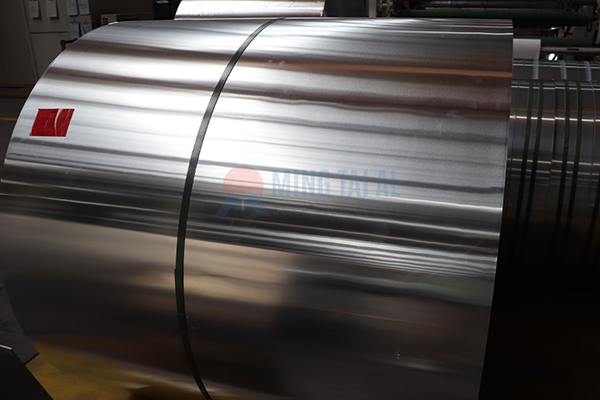

Aluminum foils for electrolytic capacitors are critical components in the electronic industry, providing the essential functionality needed for high-performance capacitors used in a wide range of electronic devices. Known for their excellent conductivity, corrosion resistance, and high capacitance, these foils play a pivotal role in the efficiency and reliability of electronic circuits. As the demand for more powerful, compact, and reliable capacitors grows, selecting the right type of aluminum foil becomes crucial to achieving superior performance and longevity in electronic applications.

Aluminum foils are widely used in electrolytic capacitors because of their ability to form an oxide layer on the surface, which acts as the dielectric. This feature makes aluminum an ideal material for capacitors, offering high capacitance in a small, lightweight form factor. The foils’ high surface area and excellent conductivity ensure that the capacitors can store and release electrical energy efficiently. Furthermore, aluminum is lightweight and cost-effective, making it an attractive choice for manufacturers in the consumer electronics, automotive, and industrial sectors.

When choosing aluminum foils for electrolytic capacitors, certain properties must be considered to ensure optimal performance:

Corrosion Resistance: Aluminum’s natural oxide layer protects it from corrosion, making it perfect for long-lasting capacitor applications. This property is especially important in environments where capacitors are exposed to moisture or high temperatures.

High Conductivity: Aluminum offers excellent electrical conductivity, which ensures that capacitors operate efficiently and without loss of energy.

Formability and Thinness: Aluminum foils can be produced in very thin gauges, which is necessary for creating compact and high-capacity electrolytic capacitors. The ability to form foils in various thicknesses also allows manufacturers to customize their products based on specific application needs.

The choice of alloy is critical to ensuring that the electronic aluminum foil meets the required specifications. Some of the most commonly used aluminum alloys for this purpose include:

1050 Aluminium Alloy: Known for its excellent corrosion resistance and high formability, 1050 aluminum is ideal for creating thin, high-surface-area foils used in electrolytic capacitors. It provides good conductivity and is cost-effective.

1060 Aluminium Alloy: Similar to 1050, the 1060 alloy offers improved strength and better oxidation resistance. This alloy is a good choice for applications requiring a balance between conductivity and durability.

1070 Aluminium Alloy: This alloy is known for its high purity and excellent electrical properties, making it ideal for high-performance capacitors. It offers exceptional corrosion resistance and is used in more demanding capacitor applications.

1100 Aluminium Alloy: With good strength and high thermal conductivity, 1100 aluminum is frequently used for capacitor applications that require enhanced heat dissipation capabilities. It is also easy to work with and form into thin foils.

Aluminum foils for electrolytic capacitors are used in various industries, including:

Consumer Electronics: Power supplies, audio equipment, and mobile devices

Automotive: Electronic systems, including power steering, lighting, and infotainment systems

Industrial Equipment: Motor control, power regulation, and signal processing

Renewable Energy: Inverters and power regulation systems for solar and wind energy

These industries rely on high-quality aluminum foils to produce capacitors that are not only efficient but also reliable in performance and longevity.

If you are looking for top-grade aluminum foils for electrolytic capacitors, our company offers high-quality alloys like 1050, 1060, 1070, and 1100, designed for superior performance in demanding electronic applications. Our experienced team is committed to providing you with the best materials at competitive prices, ensuring your products meet the highest standards.

Contact us today to learn more about our aluminum foils and how we can support your business in achieving greater efficiency and performance in your capacitor production.

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

8011 aluminum foil for aluminum bottle cap raw materials 1070 Aluminum Foil for Electrolytic Capacitors: A Key Component for Modern Electronics Alloy 8006 foil for aluminum foil container Driving Excellence in Packaging: Aluminum Foil Manufacturers in Korea Which aluminum foil is used on the inner wall of milk cartons? 8021 aluminum foil for pharmaceutical aluminum-plastic blister packaging 3004 container foil factory price 8011 aluminum foil for aluminum cooling fins

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.