Leave Us Message Author:Mingtai Aluminum

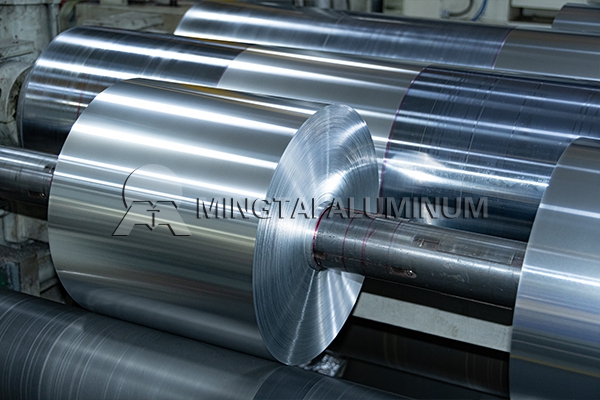

Aluminum foil is widely used in daily life, mainly for flexible packaging, packaging, food packaging, etc. Aluminum foil has long been used in lithium batteries, but its dosage is minimal, compared to the packaging industry is less than 1%. Therefore, before the aluminum foil for lithium battery is not as the main development direction of aluminum foil industry. Manufacturers are generally not spend energy and financial resources, but by the dealer to buy ordinary soft packaging aluminum foil used for cutting and screening supply battery factory.

In recent years, the use of lithium batteries has been greatly broadened, and the demand for lithium batteries is rapidly increasing. In recent years, its lithium battery production by leaps and bounds, while upgrading the technical requirements of aluminum foil. This has a certain stimulating effect on the domestic aluminum foil industry. Battery foil is becoming an independent foil variety is recognized.

It is worth noting that the safety requirements of lithium battery as part of the aluminum foil material composition. Now the aluminum foil for lithium battery should meet some requirements.

First, the cleanliness of aluminum foil is high: aluminum coil can not be mixed with any debris, dust, especially iron scrap material, the battery charging and discharging process will seriously affect its safety.

Second, aluminum foil plate shape requirements: aluminum foil surface coated cathode material uniformity, life and battery life will be greatly affected. Coating process almost no tension, which are very demanding on the shape of the aluminum foil, usually the shape of the plate should be controlled below 10I;

Third, the mechanical properties of high aluminum foil: in ensuring the purity of aluminum under the same required high tensile and high elongation, as everyone knows, the higher the purity of aluminum, the tensile performance will continue to decline, the elongation rate increased. This undoubtedly brings a difficult topic to the research of aluminum foil;

Fourth, the surface of aluminum foil surface may not have high requirements: the dark side of bright spot, black oil line, pits and various surface defects, the coating of lithium batteries and uniform compaction processes are directly related. Therefore, in the production process of aluminum foil cleaning machine and environmental cleanliness requirements are quite high.

In order to ensure the safety of the product and maintain the development of the lithium battery industry, it is necessary to set the industry standard for lithium battery. Improve the qualification of battery aluminum foil and aluminum foil into the threshold of the industry, to prevent the introduction of low aluminum foil lithium battery industry crisis.

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

8011 aluminum foil for aluminum bottle cap raw materials 1070 Aluminum Foil for Electrolytic Capacitors: A Key Component for Modern Electronics Alloy 8006 foil for aluminum foil container Driving Excellence in Packaging: Aluminum Foil Manufacturers in Korea Which aluminum foil is used on the inner wall of milk cartons? 8021 aluminum foil for pharmaceutical aluminum-plastic blister packaging 3004 container foil factory price 8011 aluminum foil for aluminum cooling fins

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.