Leave Us Message Author:Mingtai Aluminum

In the family of electrolytic capacitors, aluminum electrolytic capacitors are widely used because of their superior performance, low price and wide application. In the past 20 years, it has been greatly developed in the world. Only in Japan, for example, in 1995 electrolytic capacitor aluminum foil production of about 3000 tons, in 2001 the output has reached 70 thousand ~ 80 thousand tons, almost at an alarming rate. Electronic aluminium foil in China in Mingtai Aluminum.

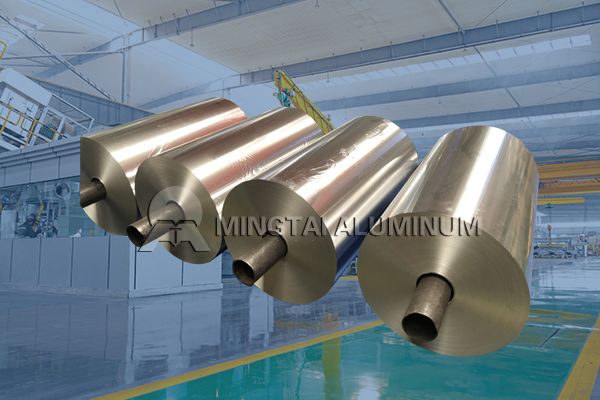

The electronic aluminium foil in China belongs to the category of electronic aluminum foil, which is a kind of corrosion material under the condition of polarity. Different polarity of electronic aluminum foil requires different corrosion types. The high voltage anode foil is a cylindrical hole corrosion, and the low voltage anode foil is sponge like corrosion.

Until the 1980 s, the electrolytic capacitor is used mostly by hand chemical corrosion, after 80 s using linkage electrochemical corrosion. Corrosion by hand with the purity of aluminum foil is low (99.3% ~ 99.7%), the requirement for the quality of aluminum foil processing is not high also. Linkage electrochemical corrosion requirements the purity of aluminum foil is higher and higher, the quality of aluminum foil processing also requires more and more pure. From the purity of aluminum, aluminum purity is 99.99% in the 1980 s, so far, the aluminum purity is 99.993%. This is the requirement of the electrode foil, and advances in technology of aluminum processing industry.

The purity of aluminum foil is improved, of course, to improve the quality of the electrode foil, but on the other hand, the cost is increasing. At the same time, the corrosive medium is also changing, some medium concentration increase, some media type change, all of the adverse environmental protection work, led to the task of environmental protection enterprises is heavy, which may decrease the purity of aluminum. Based on the analysis of the latest composition of the aluminum foil in Japan, it is found that there is a trend in this field.

To improve the quality of the aluminum foil corrosion and foil quality progress is inseparable from the Japanese patent, the patent for the 1980s peak of cathode foil, anode foil patent peak two: a peak of about 1977 ~ 1978, another peak around 1983. These patent peaks indicate that technology is advancing rapidly.

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

8011 aluminum foil for aluminum bottle cap raw materials 1070 Aluminum Foil for Electrolytic Capacitors: A Key Component for Modern Electronics Alloy 8006 foil for aluminum foil container Driving Excellence in Packaging: Aluminum Foil Manufacturers in Korea Which aluminum foil is used on the inner wall of milk cartons? 8021 aluminum foil for pharmaceutical aluminum-plastic blister packaging 3004 container foil factory price 8011 aluminum foil for aluminum cooling fins

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.